Plain Long Sleeves Sweat Suits Fashion Men Cotton Joggers S Sweat Suits Sets Unisex Training Jogging Wear From Bangladesh

(0

reviews)

Estimate Shipping Time:

5-10 Days

Price:

$424.00

/Pc

Refund:

Share:

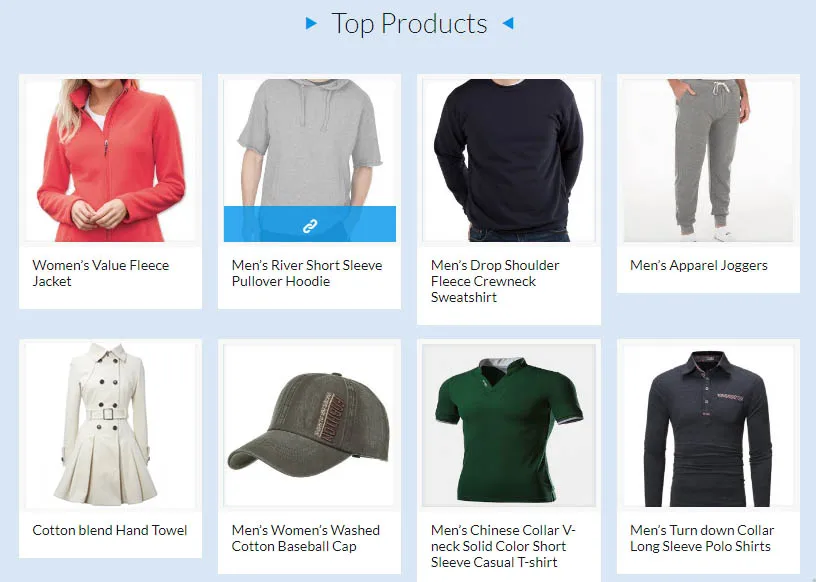

Top Selling Products

-

G2000 Women Belted Dress

$53.90 -

G2000 Women Belted Dress

$53.90

Product Description

Specification

Other Products

Recommend Products

Company Profile

We working together in some well-organized factories who are WRAP, BSCI, ISO Certified & maintain the Social Compliance standard. These factories are vertically set up with state-of-the-art machines for Knitting, Dyeing, Sewing, Automatic Printing & Embroidery and also high profile personnel adopted the social accountability international standard SA8000 and ISO Standard as well. Also we assess the factories in terms of product range, quality of the product made, production capacity, facilities, financial capability, technology orientation, man power, working conditions, managerial efficiency and their overall quality policy. Beside of our orders these factories are working with some branded customers like ; American Eagle, Wal-Mart, S.Oliver, Zara, H&M, C&A, Tesco, Next, Esprit, Marks & Spencer, Target etc. “Your Trusted Global Sourcing Partners”

The prevention part is taken care of by our Quality Assurance (QA) team which, under guidance from customers, set the standards

for quality and supervises all elements of pre-production work Such as the fitting and styling details. The prevention part is

also supported by in-house testing labs which make sure that the required testing procedures are undertaken before the production

process starts.

2) Control

The control part is taken care of by our Quality Control (QC) team, which ensures the product standards set by the customers in

co-operation with our QC team are implemented throughout The production process, and that the final products are as per our

customer’s specifications. QC service takes place before the bulk fabric is cut. It consists of the elements listed below.

• Reporting of fabrics & necessary accessories arrival status.

• Visual control of fabrics: weight/m2, color, hand feel etc.

• Forecast of production timing (starting date, assigned capacity, daily output and finish date).

• Checking with production supervisors whether they think the style is feasible in conformity with the approved samples.

Category of Inspection

Usually, Our QC carry out their inspection in four stages in accordance to the MIL-STD-105E along with AATC, ASTM and ISO codes &

standards. The level of inspections are used for the 4 pre-shipment inspections are as follows:

1. Pre-Production Check (PPC)

2. Initial Production Check (IPC) –Single Sampling Plan General Level I

3. During Production Check (DUPRO)–Single Sampling Plan General Level I

4. Final Random Inspection (FRI) – Single Sampling Plan General Level II

Design & Development:

Aaryan Apparel Sourcing Ltd” has own design and sampling section. The designers are making designs according to customer’s requirement and also they are generating new design as per present market trend and offering to the customers .We have utilized the latest computer aided systems to develop patterns and markers to thrive to ensure each pieces of apparel it makes would be an identical reproduction of the approved samples and the fabrics it uses to make those apparel would leave the minimum wastage possible. Trend Exploration: We set up a scouting team and send them overseas to scout the latest trends and designs. Once we get new ideas, we work on that. Collection Development: We constantly work on developing our collection and our scouting team plays a big role in it. They scout the latest trends and we work on setting a certain standard to it and try adding that to our collection. Thus, our collection increases and we have more to offer our customers. Service Improvement: Our one of the very main targets is to satisfy our customers, thus, we constantly work one developing our service by trying to offer better quality and bigger collection and customer service. Any complaints made or ideas suggested by the customer is taken very seriously.

Merchandising:

Merchandising:

Good merchandising is the key to successful execution of a customer’s request. Each customer is allocated to a business team which is responsible for making sure that the customer’s requirements are properly understood and executed in close co-ordination with the factories. This business team is the main contact point of the customer, and the key members of this team often travel to the customer to improve their understanding of the customer’s needs and the market. Our merchandisers are all experienced professionals, most of them having specific factory experience which enables them to

understand the requirements of the customers, as well as the capabilities and limitations of the factories. The business team is expected to contribute to the customer, not only in terms of communication and follow-up, but also in terms of making a better product which sells well at the point of sale.

understand the requirements of the customers, as well as the capabilities and limitations of the factories. The business team is expected to contribute to the customer, not only in terms of communication and follow-up, but also in terms of making a better product which sells well at the point of sale.

Quality:

The process of delivering a quality product to our customers is divided into two key areas.

1) Prevention

1) Prevention

The prevention part is taken care of by our Quality Assurance (QA) team which, under guidance from customers, set the standards

for quality and supervises all elements of pre-production work Such as the fitting and styling details. The prevention part is

also supported by in-house testing labs which make sure that the required testing procedures are undertaken before the production

process starts.

2) Control

The control part is taken care of by our Quality Control (QC) team, which ensures the product standards set by the customers in

co-operation with our QC team are implemented throughout The production process, and that the final products are as per our

customer’s specifications. QC service takes place before the bulk fabric is cut. It consists of the elements listed below.

• Reporting of fabrics & necessary accessories arrival status.

• Visual control of fabrics: weight/m2, color, hand feel etc.

• Forecast of production timing (starting date, assigned capacity, daily output and finish date).

• Checking with production supervisors whether they think the style is feasible in conformity with the approved samples.

Category of Inspection

Usually, Our QC carry out their inspection in four stages in accordance to the MIL-STD-105E along with AATC, ASTM and ISO codes &

standards. The level of inspections are used for the 4 pre-shipment inspections are as follows:

1. Pre-Production Check (PPC)

2. Initial Production Check (IPC) –Single Sampling Plan General Level I

3. During Production Check (DUPRO)–Single Sampling Plan General Level I

4. Final Random Inspection (FRI) – Single Sampling Plan General Level II

Our Advantages

FAQ

1. who are we?

We are based in Dhaka, Bangladesh, start from 2020,sell to South Asia(10.00%),Southern Europe(10.00%),Africa(10.00%),Southeast Asia(10.00%),Eastern Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(5.00%),Oceania(5.00%),Northern Europe(5.00%),South America(5.00%),North America(5.00%),Eastern Asia(5.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

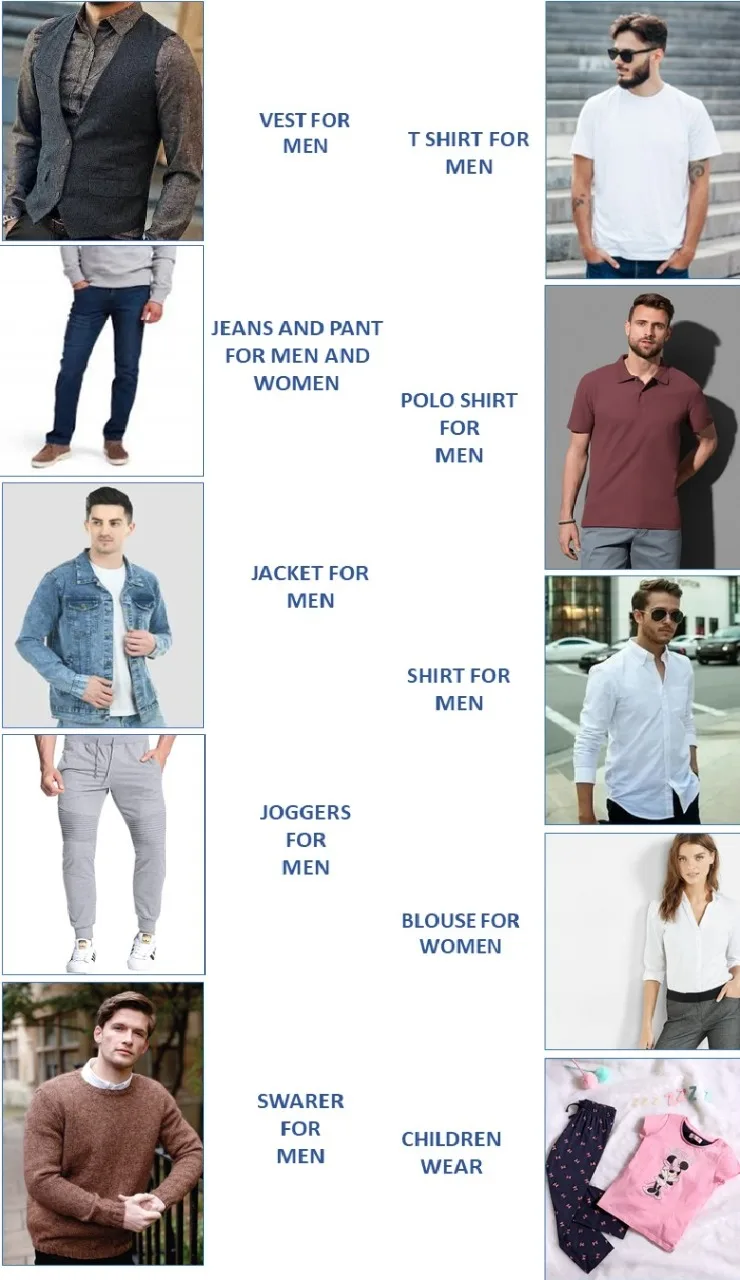

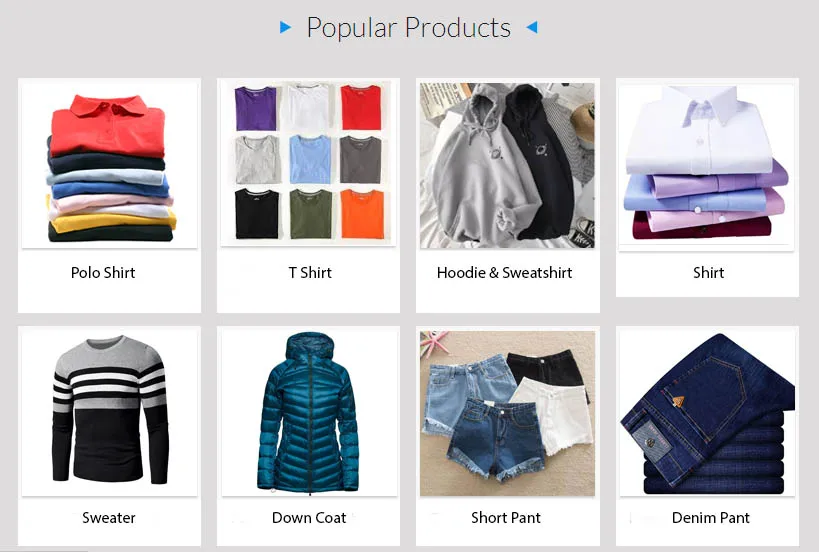

3.what can you buy from us?

T SHIRT,POLO,SHIRT,JEANS,SWEATER

4. why should you buy from us not from other suppliers?

AA SOURCING LTD is a fast-growing apparel Manufacturing, merchandising & sourcing company from Dhaka Bangladesh. we developed with multinational brands for all operations in all major production.We have been working with various famous brands for many year

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,Express Delivery;

Accepted Payment Currency:USD,EUR,GBP;

Accepted Payment Type: T/T,L/C,MoneyGram,Western Union;

Language Spoken:English

We are based in Dhaka, Bangladesh, start from 2020,sell to South Asia(10.00%),Southern Europe(10.00%),Africa(10.00%),Southeast Asia(10.00%),Eastern Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(5.00%),Oceania(5.00%),Northern Europe(5.00%),South America(5.00%),North America(5.00%),Eastern Asia(5.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

T SHIRT,POLO,SHIRT,JEANS,SWEATER

4. why should you buy from us not from other suppliers?

AA SOURCING LTD is a fast-growing apparel Manufacturing, merchandising & sourcing company from Dhaka Bangladesh. we developed with multinational brands for all operations in all major production.We have been working with various famous brands for many year

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,Express Delivery;

Accepted Payment Currency:USD,EUR,GBP;

Accepted Payment Type: T/T,L/C,MoneyGram,Western Union;

Language Spoken:English

Packing & Delivery

There have been no reviews for this product yet.